The Industrial Internet of Things (IIoT), being the basis for the Industry 4.0 and Smart Factory, provides connectivity for smart factories, machines, industrial infrastructure, management systems, and more, to streamline business operations, creating intelligent, self-optimizing industrial equipment and facilities. A number of challenges – related to the management of equipment and resources, the security and safety of people – can be addressed with innovative IoT solutions.

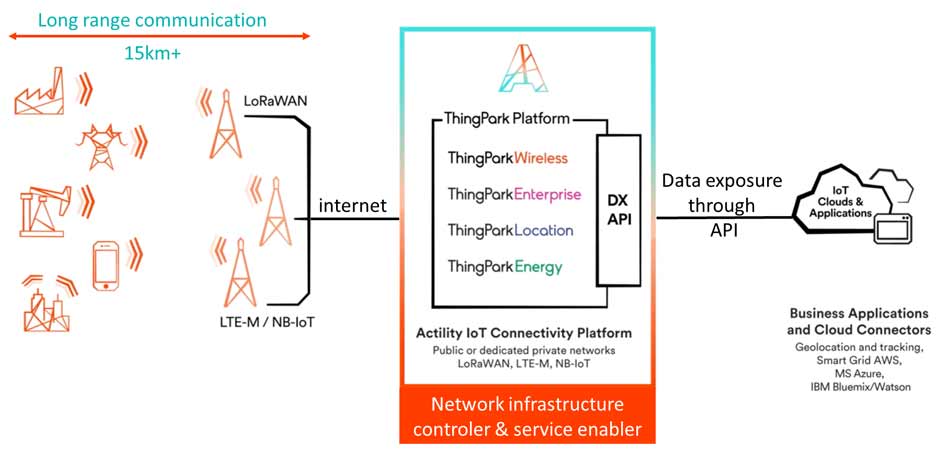

The Industrial IoT represents a fast-growing field of application of low-power wide-area (LPWA) networks like LoRaWAN™, due to its exceptionally low power capabilities perfectly suited for the industrial automation world, enabling innovative services for improving efficiency, reliability, and availability of industrial processes and products. Actility, being at the heart of an ecosystem of IoT sensors and applications makers, offers an IoT connectivity platform, ThingPark, providing its LoRaWAN™ network server and software to manage both private and public networks, under a unified, scalable, multipurpose IoT network infrastructure.

Industrial IoT solutions for smart manufacturing, powered by Actility’s LoRaWAN™ technology, allows the harnessing of the power of data in order to streamline operations, reduce maintenance costs and ensure quality in the manufacturing process.

Strengthen airport operations, improve safety and services for travelers and reduce operating costs by connecting critical airport assets and installations with highly-secure LoRaWAN™ connectivity.

Connecting trains, equipment, tracks, stations, and the operations center using LoRaWAN™ allows to lower operating expenses and to simplify maintenace globally for railway infrastructure operators.

The Internet of Things is breaking fresh ground for car manufacturers and vehicle fleet operators by allowing them to streamline development of connected car applications, to improve fleet management, maintenance and safety

Most mining, oil drilling and gas production is done in remote and harsh environments, presenting connectivity challenges now being addressed by Actility with LoRaWAN™ technology. By securely connecting assets and installations, risks are controlled and the production of natural resources is maximized.

IoT provides many solutions to the problem of site management, the monitoring of the use of construction equipment, the prevention of theft, and the work done by men. Construction companies are now able to optimize their on-site activities using LoRaWAN™.

LoRaWAN™ has the lowest cost for network infrastructure deployment and maintenance thanks to its high link budget, long range, good redundancy and ease for scaling densification.

Cities have the choice to either deploy their own city-scale LoRaWAN networks or leverage existing public ones. The network serves existing business units and can be built on existing city infrastructure.

Very low-power bi-directional communications, deep indoor penetration and can work in a remote, harsh environment, high reliability of the network infrastructure and the sensors

LoRaWAN industrial sensors are optimized for a battery life of up to 15 years, and for transmission frequency, LoRaWAN offers one of the best options for mitigating battery life issues through network densification.

The LoRaWAN specification uses 128-bit Advanced Encryption Standard (AES) algorithms to provide end-to-end encryption using two keys: one for the users, for protection of payload content; another for operators, for network authentication security.

Cities have the flexibility to integrate devices from multiple vendors and benefit from interoperability at the network level.

You can buy devices like sensors and trackers for your various Smart Industry use cases off-the-shelf on ThingPark Market, the largest catalog of IoT devices and applications, powered by Actility

Industrial facilities and sites in key sectors like manufacturing, railway, construction, oil & gas, and many others currently face a number of challenges:

It’s more practical and compelling than ever to connect manufacturing equipment to a Web-based network, deriving substantial value from it. The Internet of Things, harnessing the benefits of low-power wide-area (LPWA) networks like LoRaWAN®, allows adding digital sensors and networking technologies to the devices and systems of the analog world.

Actility is focusing on the Industrial IoT, which deals with connectivity for smart factories, machines, industrial infrastructure, management systems, and more, to streamline business operations. The Industrial IoT is the basis for the Industry 4.0, which refers globally to the use of automation and data exchange in manufacturing, also using robotics, system integration, cybersecurity, the Cloud, data analytics, and augmented reality. These technologies are used to create a “smart factory” where machines, systems, and humans communicate with each other in order to coordinate and monitor progress along the assembly line.

IoT applications for the Industry 4.0, using those Intelligent sensors and low-power connectivity, are driving operational efficiency through automation, connectivity and analytics in manufacturing and operations, asset management, planning and inventory, quality sensing and prediction, condition-based monitoring in industrial plants and manufacturing facilities.

The payoff for manufacturers who implement Industrial IoT solutions lies in better decision-making. When devices are connected, the data they generate can flow into software applications that create the information individuals can use to make choices that are timely and effective. By understanding the results of these choices more fully, decision-makers can achieve strategic objectives or benchmark performance. Better decisions mean fewer mistakes and less waste.

Connecting machines and utilizing directly applicable real-time information allows to optimize performance, perfect maintenance cycles and improve productivity. Perhaps the most positive and encouraging aspect of the Industrial IoT and Industry 4.0 is the explicit acknowledgment that the individual human being will continue to play an active, engaging role in manufacturing. Therefore, people’s safety is one of the main achievements of IoT implementation in industrial environment.

LoRaWAN™ is becoming widely used and helps to achieve the target of implementing predictive maintenance, industrial assets and environment control, energy consumption monitoring, and other solutions in a very efficient way. To sustain such kind of solutions, local on premises private networks in particular are becoming very used into the industrial applications, mainly for the benefits related to security, low latency, and data transfer optimization. To make it possible, Actility provides its LoRaWAN™ network server and software to manage public or private networks, under a unified, scalable, multipurpose IoT network infrastructure. A single platform facilitates the deployment, operation, and maintenance of your industrial projects, and LoRaWAN™ ensures that you know the vital data of your systems.

LoRaWAN™ offers long range (up to 15km) bi-directional communications with very low power consumption, deep indoor penetration and very low Total Cost of Ownership. LoRa-enabled sensors detect and measure physical characteristics or conditions of a device (on/off states, amperage draw, temperature, pressure, vibration levels) and perform other functions, like using geolocation technologies or converting analog readings into a digital format. Moreover, you save the installation of cables with battery-powered LoRa sensors.

LoRaWAN™ offers long range (up to 15km) bi-directional communications with very low power consumption, deep indoor penetration and very low Total Cost of Ownership.

LoRa-enabled sensors detect and measure physical characteristics or conditions of a device (on/off states, amperage draw, temperature, pressure, vibration levels) and perform other functions, like using geolocation technologies or converting analog readings into a digital format. Moreover, you save the installation of cables with battery-powered LoRa sensors.

The LPWA network is a cost-effective solution which allows smart industries to have complete control of the network and data with only a few base stations, and managing sensors and devices with a very low Total Cost of Ownership. Once the network is deployed, it’s easy and cost-effective to expand the value of the network investment over time by adding new devices. It also provides standardized, robust security; state-of-the art network management tools; and high quality of service. Through an ecosystem of partners utilizing Actility’s interoperable platform, industries can now leverage significant advancements in IoT technology, including multi-application networks; cloud computing; data analytics; and a new generation of battery-powered edge devices and sensors. All these technologies come together in our IoT connectivity platform that delivers new and differentiating value to enable smart utilities.

The market leading, most complete, powerful and flexible multi-technology LPWA IoT Network platform. ThingPark Wireless is the preferred IoT network platform for Service Providers rolling out LPWA connectivity services, already powering over half of national LoRaWAN™ network deployments worldwide .

ThingPark Wireless is the heart of your IoT network, enabling secure connectivity, data flow, and management from sensors to cloud applications. ThingPark Wireless is modular, and scales easily, enabling Service Providers to monetize connectivity and accelerate the adoption of IoT solutions across multiple industries.

With ThingPark, become part of a thriving community of innovators shaping the future of IoT. Our platforms are more than products—they’re a springboard for collaboration, growth, and the realization of transformative IoT solutions.